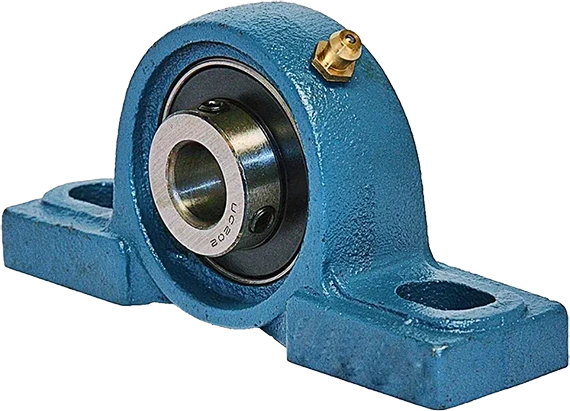

Sturdy supports for shafts in demanding setups keep things running smooth, handling tough loads while cutting back on shakes and breakdowns across rough sites like mines or clean rooms in food plants. Built tough, these parts stand up to the grind, making sure machines stay productive without constant fixes.

Top-notch steps in pillow block bearing manufacture turn out units ready for harsh jobs, mixing strong stuff with smart tech to push limits on strength and smooth spins. It all begins with picking the right base and rolls through tight controls, ending up with bearings that tackle real challenges head-on.

Tough cast iron, flexible ductile iron, and solid steels get pulled in for their grit against constant pounding. Hot metal flows into sharp molds, crafting bases that shrug off twists in heavy-duty spots like rock handlers or factory lines.

Precision CNC setups shave down pieces to super-fine edges, hitting marks as close as microns to keep friction low. Turning tools shape tricky bits, locking in steady output even on massive runs.

Pieces go through hot soaks and fast chills to crank up toughness, standing firm against scrapes from dirt in fields or builds. This ramps up staying power in nonstop pushes.

Coats of zinc or tough seals fend off rust and eats from wet or chem-heavy zones, like shores or mix plants. Last polishes wipe out rough spots that might kick off early wear.

Parts snap together with thick greases made for long hauls between checks. Shakers and force gauges run drills, kicking out any that don't hit marks on quiet runs or steady turns.

Different builds in pillow block bearings match up to odd needs, from straight holds to ones that shift with bends or watch their own health. These picks slide into setups easy, often skipping big changes.

Basic ones take on everyday weights in shops or water pulls, simple to set and cheap for belt pulls or plain gear.

Rounded insides fix shaft twists up to degrees, great for stretched runs where lines drift, easing hits on linked stuff.

Thick shells soak up huge pushes, excelling in stone breakers or roll presses under jolts and bulk.

Closed kinds with mixed bits whirl over thousands of turns, stainless ones battle acids, slotting into drug stirs or sea wind gears.

Sharp focus on fresh ideas lifts DEC Bearings up with top pillow block bearing manufacturers India, weaving old skills with new tools to hit world calls. Geared for fast mocks and big batches, it keeps shipments rolling without skimping on solid make.

Big spread in Gujarat loads up on robot arms and sealed test spots, pumping out loads monthly with misses close to none.

Sticks to ISO, IATF, ASTM marks, promising steady work overseas, with full trails from start to ship.

Tweaked fits for odd sizes or mixes help makers build standout rigs, sharpening edges in tight fields.

Sends to heaps of lands, with chains trimmed for quick drops, helping cut stock piles far off.

Links with key outfits in cars, digs, and clean power show how pillow block bearings India hold steady in tough flows.

Trusted by OEMs across industrial machinery, mining and automation sectors worldwide.

Handy pillow block bearings fit where steady spins tie to output and safe runs. Their grit shows in spots with wild weights or rough airs.

Crop cutters and water feeds fight mud and endless moves, trimming stops in busy times.

Closed ones in eat or pill lines hold clean while taking mixed heaps.

Blend rigs and load hauls take shocks from bumpy ground and thick stuff.

Way down, pillow block bearing manufacture battles grit and squeeze in belts and bores.

Arm bots and wrap gears use quick kinds for spot-on, fast jobs in auto hubs.

Shift kinds handle thread tugs in weave sets, stretching check gaps.

Tough pillow block bearings India back turbines and sun chasers in open roughs.

Standout make puts DEC Bearings ahead in pillow block bearing manufacturers India, handing real ups in last and flow.

| Feature | DecBearing | Typical Market Offerings |

|---|---|---|

| Precision & Quality | Fine CNC slices and auto scans | Rough hands with wide slips |

| Customization | Quick mocks for special calls | Slim picks, slow builds |

| Lead Times | Trimmed paths for weeks' waits | Stretches to months |

| Testing | Deep checks on shakes and hold | Quick looks only |

| Support | Steady advice and spare stocks | Thin guides, spot helps |

Partner with our engineering team for specifications, OEM collaboration, or bulk requirements.

1. How to choose right pillow block bearings?

Weigh shaft width, weight kinds, turns, and spot risks like hot or dust for top fit.

2. What drives pillow block bearing prices?

Picks in builds, holds, fine cuts, guards, and extras like closes all count.

3. What fixes pillow block bearing span?

Firm sets, usual oils, and line watches stretch years, specially in even runs.

+91 - 96877 77708

info@decbearing.com

268 / 269, G.I.D.C., Wadhwan City - 363 035, Gujarat, India.