Pillow block bearing production quality control is an essential process that checks each bearing for the industry standard of durability, precision, and performance. To produce the pillow block bearings, the process starts with raw material inspection, wherein the inspection is done on good-quality steel or cast iron for wear resistance and toughness property.

Eliminating the dimensional inaccuracies is done through advanced machining and grinding processes ensuring a proper fit and smooth operation. After the bearings have passed heat treatment that improves hardness and longevity, lubrication and sealing checks follow to avoid contamination, and friction is assured.

After all, qualified tests performed include the capacity for load, vibration analysis, and endurance tests to ensure the bearings qualify under real-world conditions. Finally, each bearing goes through corrosion resistance treatments and visual inspection before going into packaging. Strict quality control at every single stage ensures that every pillow block bearing gives long-term service and efficiency in a wide range of industrial applications.

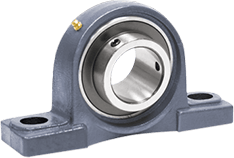

There are various types of pillow block bearings, each designed for certain industrial needs and conditions for operation. Mounted housings fitted with self-aligning bearing inserts constitute a standard pillow block bearing making it suitable for a universal connotation for application on conveyors, fans, and agricultural equipment.

High-speed machinery, such as electric motors and textile machines, predominates in using ball-bearing pillow blocks whose function is smooth operation with low-friction. Heavy loads are well balanced with roller-bearing pillow blocks. These are employed for applications that demand high loads, as in mining, construction, and industrial processing.

Split pillow block bearings are used when flanged-bearing assembly and disassembly is easy, thus applicable on machinery that requires frequent attention. Sealed and corrosion-resistant pillow block bearings are also designed for extreme environments such as food processing and marine conditions, where moisture and contaminants must be kept away.

These types allow industries to choose the appropriate pillow block bearings which would be desirable to high productivity, low downtime, and better features of a machine as a whole.

When you are left with no option but to decide between pillow block bearings and any other bearings, there are several things that you need to consider such as load capacity, requirement for alignment, and application condition. They are simply meant for those shafts which are fixed immovable; because they are self-aligning and easily installable, they are meant for conveyors, fans, and agricultural machinery.

But for high-speed applications like those in electric motors and components of an automobile, deep groove ball bearings are ideal due to low friction and investment return. Roller bearings, whether cylindrical or tapered, are the best suited for most situations with high weights being held, usually found in mining and construction.

Flange bearings are also ideal for diverse vertical angle shafts; they are mainly used in food processing as well as packaging industries. Should your application require same in installation access, the ability to install or align moderately, and the handling of loads, then go with those pillow block bearings.

However, at the extreme speed or extreme load levels, or for very particular applications, then there are typically other types of bearings best suited. The right bearing will ensure optimal machine performance as well as extended life and a decrease in maintenance.

Pillow block bearing producers make use of modern machineries that uses cutting edge technologies for manufacturing high quality Pillow block bearing that can be utilized in several industries. These bearings are corrosion free, made of high-quality materials that can sustain harsh environment.

Another new trend that will be popularized is smart bearings through IoT sensors, which enable online temperature, vibration, and wear monitoring toward predictive maintenance for industrial applications. These trends will make pillow block bearing manufacturing bright as they are also oriented toward energy-efficient designs using low-friction components in usage for energy consumption reduction and operational efficiency enhancement.

Customization of pillow block beaks on a specific industry, as in food processing and heavy machinery, is high in demand. Automation and precision engineering are advancing with time; hence, all of the above trends are shaping tomorrow's horizon of pillow block bearing manufacture with reliability at a lower cost for almost every industry.

Pillow block bearings help ensure smooth operation, minimal maintenance, and higher efficiency within all industries they are found in. Their stringent quality control thus guarantees durability, precision, and long-lasting performance through a rigorous quality-compliant process in its manufacture.

The various types of pillow block bearings, therefore, enable an industry to settle for maximum suitability based on the needs being addressed, whether for high-speed, heavy load, or corrosion resistance applications. The comparative analysis of pillow block bearings and other bearing types helps businesses decide the best applicable choice among them, depending on their machines, for optimal functionality of the machinery and, consequently longevity of use.

Also, some emerging trends such as those from high-performance materials, IoT-enabled smart bearings, and energy-efficient designs have much to do in the change of the industry. Innovation, precision, improvement, and so on are put to action as technology evolves further for the needs of modernization in industries. A reliable pillow block bearing manufacturer will therefore give quality products that improve operational efficiency toward a long-term success.